Manufacturing variance

The quality of contemporary industrial printing is truly outstanding. However, like any mechanical process, there may be very slight variations.

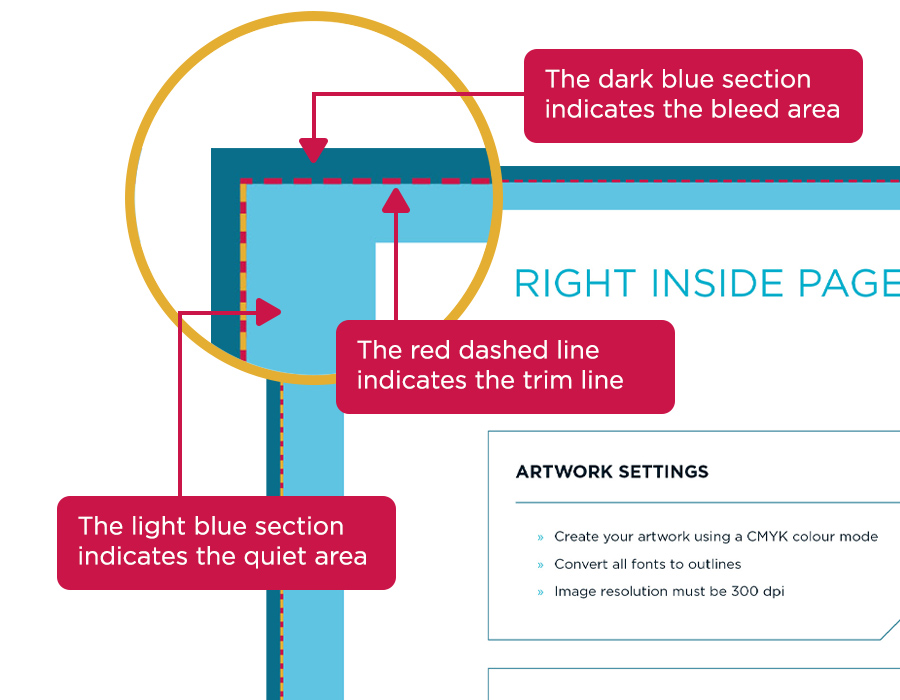

Trim, bleed and quiet areas

Even the finest printing machines aren't immune to tiny margins of error. During large print runs, as thousands of sheets are precisely cut, there may be a slight shift in their alignment, typically less than 1mm, which could cause minute variations from one piece to another.

That’s why it’s crucial to include a ‘bleed’ in your projects, printing past the intended trim line. This ensures that any minor discrepancies in cutting don’t reveal any unprinted edges. Always incorporate a bleed in your print files and consider our advised quiet area to keep key design elements clear of the page's edge.

Full bleed printing file setup - link

Moreover, in high-volume litho printing using 4 colour CMYK ink from metal plates, colours can shift ever so slightly. To counter this, we print lighter colours first and darker colours afterwards. This approach helps prevent any visible white lines between colour blocks if there’s any shift during production.